In early 2020, the world experienced a coronavirus pandemic (COVID-19). In every city around the world, much of the global population was placed under restrictions of some kind.

This discussion will present solutions and strategies that fulfil the promise of healthier, more sustainable cities for the generations to come.

Filter: Industrialisation

Virtual Event

Covid-19 health emergency: what changes in the way you work on site?

From design to the construction site:

The case of the Principality of Monaco

The Covid-19 health emergency has changed both the way of living in the short term, and that of working in the long term. In order to achieve the primary objective of ensuring health and safety of employees on the construction site, the construction world has realised what are the restrictions and working conditions brought by new rules and procedures related to social distancing.

From on-site to off-site construction

From the design to the construction phase, the greatest challenge is related to physical distancing on the working site. To address this topic, one solution consists in the transition from a traditional on-site way of building to off-site construction.

To read the full article

The 4 main advantages related to the application of Lean production to off-site construction

Construction, and more in general the construction industry, do not include activities that may be directly comparable to other sectors, such as the manufacturing and production industry. It is essential to identify, regarding the construction industry, those processes that represent continuous improvements of “Lean production”, and that are usually related to a product, rather than a process. By process, we mean the sequence of activities that go from the design of a building to the organisation of the construction site, including all phases of development and planning. This first academic article aims at introducing the reader to the context of “off-site” construction and its applicability in a Lean context, highlighting the benefits related to the adoption of a prefabrication system for the achievement of business and construction objectives, such as:

- time and cost certainty;

- quality and control of the finished product;

- increased safety for the operators on site;

- responsible use of resources and reduction of overall building waste.

To read the full article

Fire Resistance of Composite Structures

In steel structures and as well as for composite structures, the only effective method to ensure the correct classification of mechanical resistance to fire is to proceed with Fire Engineering and the analytical verification methods provided by the Eurocodes. In particular, we refer to the second part of Eurocode 3 and the second part of Eurocode 4 as regards steel-concrete structures.

Within these standards are all the chemical-physical characteristics of the basic materials and also the thermo-mechanical characteristics of these elements during the increase in temperature and therefore the modification of the original properties.

From the calculation point of view, any professional engineer can perform it if properly guided through a procedure or tutorial that is normally available within the Eurocodes themselves.

It starts with the thermal analysis of the individual elements and then it extends to the thermal analysis of the entire structure.

Watch the video to learn more.

06 May 2020

Adapting Urban Density in the Age of Pandemics

The world is facing the effects of COVID-19 and questioning the responsiveness of dense cities towards this crisis, namely regarding their ability to adapt to similar events in the future.

Virtual Event

available on

https://www.ctbuh.org/events/singapore-6-may-2020

Singapore

Application Areas of Steel-Concrete Composite Structures

Composite structures as well as structures of the NPS® System can normally be applied in residential settings, service facilities as well as large infrastructures. These are industrial systems developed to streamline installation on site, to achieve maximum speed in the construction stage.

The system is normally best suited for buildings of at least three storeys or for spans from 8 to 15-16 metres. That’s the ideal target for this kind of system. However, any special applications must be assessed on a case by case basis. These structures are normally suitable for raising buildings and to absorb false loads deriving from superstructures due to the very nature of these structures, whose metal part is larger so they are hardly subject to phenomena such as viscosity and ageing.

Also with regard of assessing how to use this technology, we are often asked how compatible are these systems with other construction technologies such as cast on site, metal structures or wooden structures, for instance, as well as others, of course. Basically, composite steel-concrete structures are actually metal elements, hence they enjoy all the attending benefits. The flexibility of steel, from the point of view of calculation as well as production and installation.

Watch the video to learn more.

30 January 2020

NPS Steel-Concrete Composite Structures SEMINAR

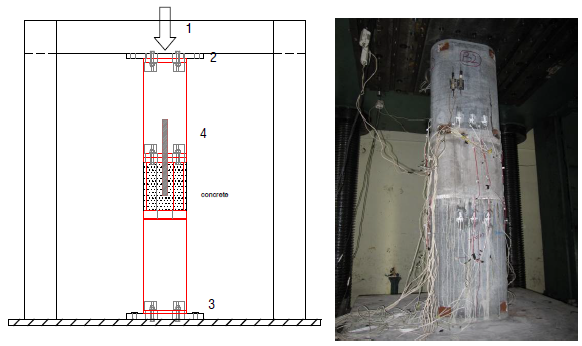

Experimental characterization of spun columns in HSC (High Strength Concrete)

The research activity at the Tongji University (China)

Since the Second World War, the common practice in the construction of civil and industrial buildings has favoured the use of prefabricated structures. Specifically, industrialized reinforced concrete columns designed to make pendular structures have been by far the most successful linear element among elevated structures. The benefits derived from this choice are mainly connected to the speed of the construction phases and the increase in the quality of the building.

With the refinement of industrialized manufacturing techniques and the performance of the concrete itself (according to the most modern FPC and according to European classifications such as EN 206), the performance of the aforesaid buildings have remarkably increased.

To read the full article

How to raise an existing building without burdening the foundations

The case of the Fonderie Arizzi in Bergamo

The case history reports an important intervention aimed at raising and adjusting a level in an existing building, consisting of two floors, located inside the Fonderie Arizzi in Val Seriana, province of Bergamo (Italy).

The need to extend the space vertically by transforming the top slab, which previously served only as a cover, determined the peculiarities of the work in a building erected many years before and used as the administrative headquarters of the company.

To read the full article

Comparative LCA of traditional structures and the NPS® SYSTEM

In Europe, the construction sector has a significant impact on the environment. This is due not only to the operation of the buildings, but also to the production of construction materials and the disposal of construction and demolition waste. For this reason, it is important to carry out an environmental assessment of the buildings by considering their entire life cycle.

To read the full article